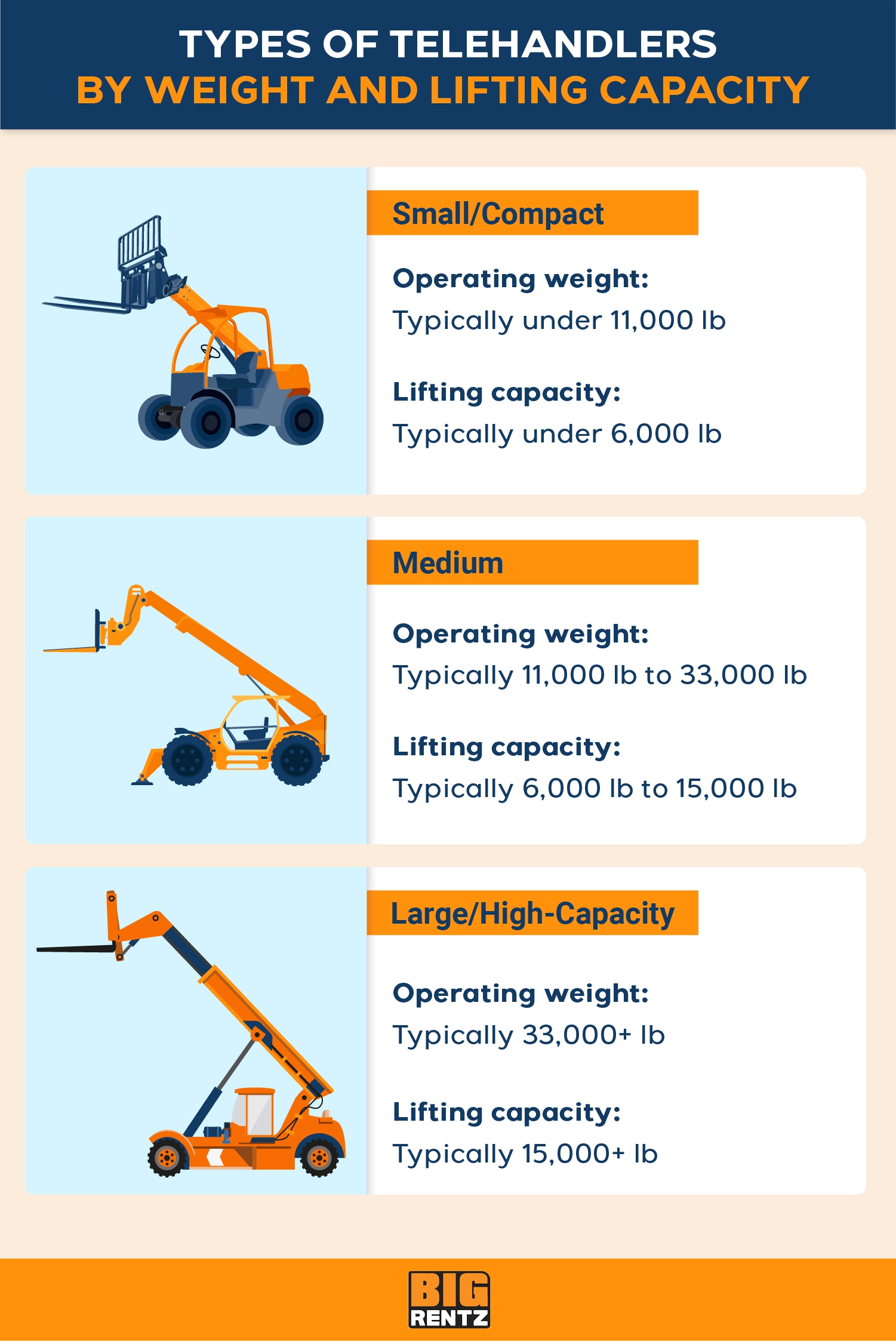

Also known as high-reach forklifts, telescopic handlers combine the lifting ability of a forklift with the extended reach of a crane. Telehandlers typically have the following operating weight based on their size:

- Small/Compact: Typically under 11,000 lb

- Medium: Typically 11,000 to 33,000 lb

- Large/High-Capacity: Typically 33,000+ lb

The larger the telehandler, the higher the lift capacity. Each model has a maximum lift capacity based on the operating weight of the machine. A telehandler’s weight affects its suitability for the jobsite and the load it can carry safely without tipping over.

In this post, we explain telehandler machine weights and lifting capacities, plus how to choose the right telehandler for your project.

Explore All Telehandlers

Table of Contents

- Telehandler Weight and Lifting Capacity

- How to Choose the Right Telehandler Size for Your Project

- Telehandler Safety Tips

- Rent a Telehandler From BigRentz

Telehandler Weight and Lifting Capacity

Telehandlers are heavy machines that exert a lot of surface pressure, so even if they can handle rough terrain, they can still get stuck in mud or soft ground. In addition, the further the boom extends, the less weight a telehandler can carry.

This means you need to calculate both load weight and reach height when deciding which size telehandler you need.

Small/Compact Telehandlers (Under 6,000 lb Lift Capacity)

Small/compact telehandlers are best for jobsites that require maneuverability, such as warehouses, small construction projects, and light agricultural work. If you have a job with lighter material handling needs requiring a lower max lift height and shorter max reach, consider renting the following compact models from BigRentz.

| Telehandler Size | Model and Spec Sheet | Machine Operating Weight | Maximum Lift Capacity |

| 19 ft Telehandler | JLG G5-18A | 11,000 lb | 5,500 lb |

| Genie GTH-5519 | 10,360 lb | 5,500 lb |

Medium Telehandlers (6,000 to 15,000 lb Lift Capacity)

Commonly used in construction, medium telehandlers offer versatility by balancing maneuverability with lifting capacity. BigRentz offers multiple midsize telehandlers with a range of maximum forward reach abilities and maximum lift capacities.

| Telehandler Size | Model and Spec Sheet | Machine Operating Weight | Maximum Lift Capacity |

| 36 ft Telehandler | SkyTrak 6036 | 21,300 lb | 6,000 lb |

| Genie GTH-636 | 17,600 lb | 6,000 lb | |

| 42 ft Telehandler | SkyTrak 6042 | 25,100 lb | 6,000 lb |

| SkyTrak 8042 | 27,100 lb | 8,000 lb | |

| Genie GTH-844 | 22,600 lb | 8,000 lb | |

| 42–45 ft Telehandler | JLG 943 | 24,912 lb | 9,000 lb |

| 42–48 ft Telehandler | Skytrak 10042 | 27,300 lb | 10,060 lb |

| JLG 1043 | 26,235 lb | 10,000 lb | |

| 55 ft Telehandler | JLG 1055 | 31,559 lb | 10,000 lb |

| SkyTrak 10054 | 28,200 lb | 10,000 lb | |

| Genie GTH-1056 | 30,000 lb | 10,000 lb | |

| SkyTrak 12054 | 30,357 lb | 12,000 lb | |

| JLG 1255 | 33,960 lb | 12,000 lb | |

| JLG 1255 | 33,960 lb | 12,000 lb |

Large/High-Capacity Telehandlers (15,000+ lb Lift Capacity)

Large telehandlers are best for heavy-duty construction or industrial work and may have advanced features. If your job involves extra heavy loads, the following high-capacity telehandler models from BigRentz can offer the lift capacity and maximum reach you require.

| Telehandler Size | Model and Spec Sheet | Machine Operating Weight | Maximum Lift Capacity |

| 44 ft Telehandler | JLG 1644 | 33,660 lb | 15,650 lb |

| Genie GTH-1544 | 33,686 lb | 15,000 lb | |

| SkyJack ZB2044 | 45,000 lb | 20,000 lb |

How to Choose the Right Telehandler Size for Your Project

When selecting which size telehandler to rent, consider the following factors:

1. Assess the Jobsite Conditions

Think about the conditions at your worksite when choosing a telehandler, including whether there may be high winds, rough terrain, unstable ground, and/or mud.

Heavier telehandlers may have difficulty with slopes, get stuck in mud, or become unstable on soft surfaces. Because of their increased weight, larger telehandlers can also damage the surface you’re working on. Heavier telehandlers are typically suitable for outdoor work in open spaces, while indoor projects may require a lighter, more maneuverable model.

2. Use the Load Chart to Understand Lift Capacity

The telehandler’s weight directly affects how much it can lift. The heavier the telehandler, the more it can typically lift because the weight of the machine counterbalances the load. For that reason, the further from the chassis the load is lifted, the lower the weight the telescopic boom can handle. Exceeding the lifting capacity can cause the telehandler to tip.

In addition to considering the machine’s weight, maximum lift height, and lift capacity, look at the load chart on the spec sheet to find the lift limits relative to the boom position. Any attachments used will also affect lift capacity, so be sure to check these in the load chart too.

3. Prioritize Stability

Bigger, heavier telehandlers are often more stable because of their mass, and they may also have outriggers or other stabilizers. Make sure you choose these if you need added stability for difficult terrain. Before lifting loads, always refer to the load chart and make sure the machine is stable. Don’t use a machine without a load chart.

4. Make Proper Transportation Arrangements

Large and heavy telehandlers can be more difficult to transport, sometimes requiring special transportation arrangements or permits to be driven on roads. Renting a large telehandler can bypass this problem, as equipment rental companies like BigRentz can deliver the machine directly to your work site.

5. Consider Fuel Capacity and Maneuverability

Heavier machines typically use more fuel, so you should include fuel costs in your budget. They may also have a bigger turning radius than smaller telehandlers, making them more difficult to control on jobsites with obstacles, such as other workers or complex layouts.

Telehandler Safety Tips

To reduce the risk of accidents while operating a telehandler, make sure to follow proper training requirements and safety protocols.

- Get OSHA-approved certification. All telehandler operators must receive certification under the Occupational Safety and Health Administration (OSHA) standard 1910.178.

- Conduct pre-operation safety checks. Before using a telehandler, inspect the components and function of your machine. Also assess the work site for potential hazards, including overhead power lines, obstacles on the ground, and any other potential issues.

- Follow the operator guidelines. Know and follow the operating instructions, load capacity, and other manufacturer’s requirements for your telehandler.

- Ensure stability and always consult the load chart. Do not operate a telehandler without a load chart for that model. Make sure that the load weight and center of gravity does not exceed the maximum capacity for that particular machine or attachment.

- Practice good operating habits. Secure the load to avoid falling debris, keep the boom as low as possible when moving the telehandler, and always operate the machine at safe speeds.

- Don’t jump from the machine if it tips over: Tip-overs can happen, and even if you follow safety protocols, you should be prepared to handle them. Your first reaction is likely to jump, but despite your instinct, for your safety, keep your seatbelt fastened and stay inside the cab. Use the steering wheel to brace yourself and help you to lean away from where the impact is likely to occur.

Rent a Telehandler From BigRentz

Whether you need a small machine for an indoor project or the heavy-duty capacity of a 44-foot model, BigRentz has a variety of telehandler rentals to suit any project.

Explore All Telehandlers