If you’re facing construction or maintenance projects that require you to work above ground level, you’ll need a boost. Depending on your worksite and the nature of your job, you may want to consider a boom lift or a scissor lift.

Boom lifts move horizontally and vertically, whereas scissor lifts can only move up and down. While boom lifts attain a greater vertical reach, scissor lifts have larger platforms with higher weight capacities, enabling them to carry multiple people along with loads of material.

We’ll explain the main differences between boom lifts and scissor lifts to help you choose the right equipment for your next project.

Explore All Boom Lifts Explore All Scissor Lifts

What Is a Boom Lift?

A boom lift is a piece of lift equipment that elevates a worker in a small bucket or on a compact elevating work platform. This type of aerial lift features a grounded base and hydraulic lift system.

Zero-emission electric boom lifts can be used indoors or outdoors, while diesel or dual-fuel boom lifts are designed for outdoor use. Electric lifts can extend from 30 to 60 feet high, while diesel-powered lifts can go from 30 feet all the way up to 210 feet. Their hydraulic arm allows for greater maneuverability, and some models can rotate 360 degrees.

Here are some pros and cons to choosing a boom lift for your construction or maintenance project:

Pros

- Can extend to great lift heights.

- Highly maneuverable.

- Lightweight and narrow for use in tight areas.

- Good for a variety of projects including:

- Piping work.

- Exterior cleaning.

- Maintenance projects.

Cons

- Smaller platforms or buckets limit how much it can carry.

- Platforms typically have room for just one worker.

- Typically more expensive to rent than a scissor lift.

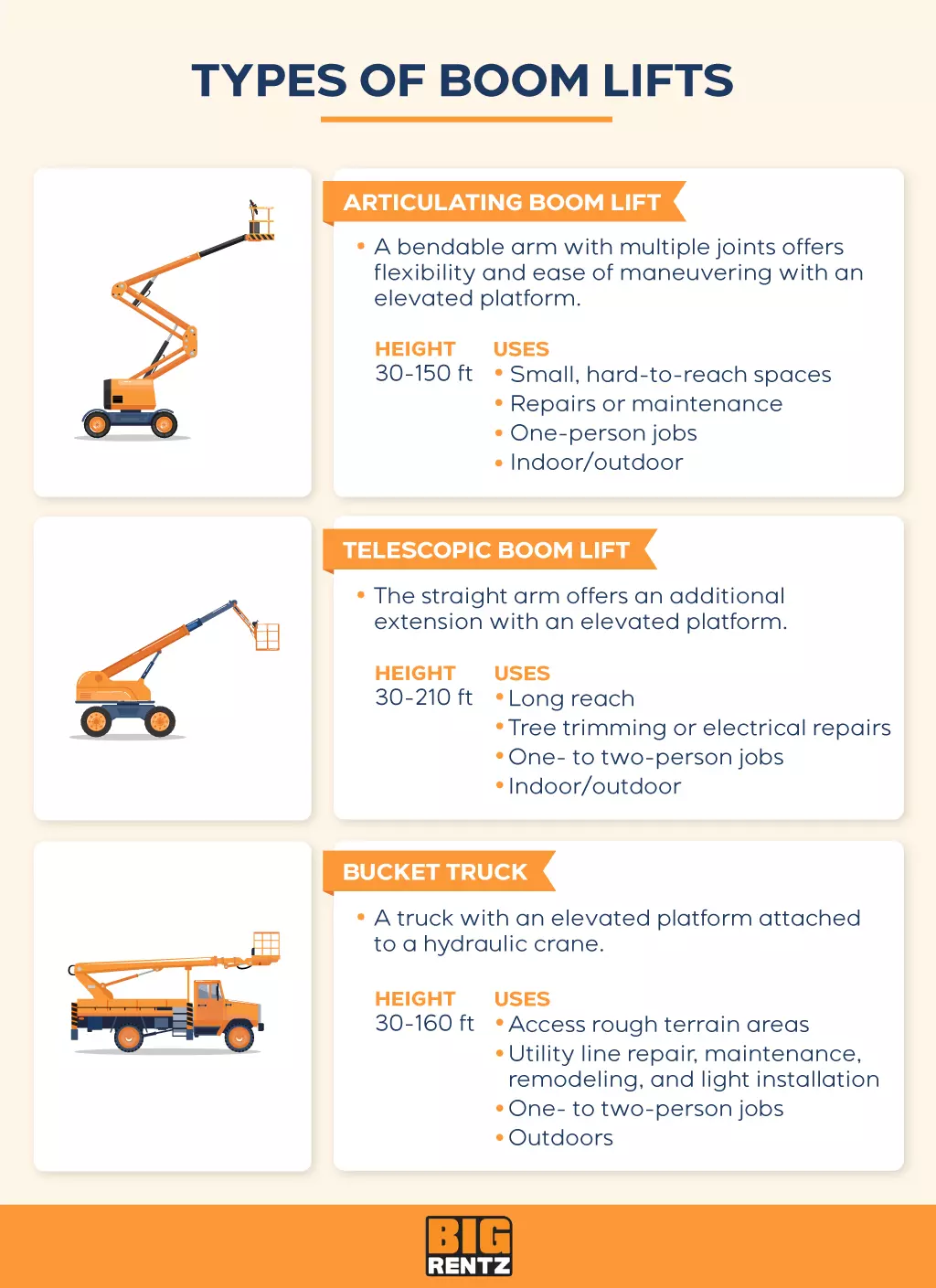

Types of Boom Lifts

These lifts — also known as man lifts, aerial lifts, or cherry pickers — come in three primary varieties: articulating boom lifts, telescopic boom lifts, and bucket trucks.

- Articulating boom lift — The “knuckled” arms allow for these lifts to bend around corners and obstacles, such as exterior walls. This can be useful when accessing items in crowded warehouses or in moving around exterior worksite obstacles.

- Telescopic boom lifts — These lack the joints of an articulating boom lift and are instead equipped with straight arms that expand or contract like a telescope. These can be used for projects such as bridge work, where a long reach is needed, or for maintenance work on highrises, which may require greater height.

- Bucket truck — This type of lift is a truck-mounted aerial platform attached to a hydraulic crane; it’s often used to access trees and utility lines. They’re also known as cherry pickers because they’re often used for orchard work, but they can also be used to prune tall trees like eucalyptus and palms.

What Is a Scissor Lift?

A scissor lift is a piece of equipment with a large, flat aerial work platform supported by a series of crisscrossed braces. These braces squeeze together to push the platform upward. The base of the scissor lift needs to sit on flat, stable ground directly beside the workspace for the project to be accessible to those on the lift.

Scissor lifts can extend from 10 feet up to 60 feet high in a straight vertical direction. They’re available in electric versions that can be used indoors and are ideal for providing vertical access so you can stack or unload inventory. They also come in four-wheel-drive, rough-terrain models that can navigate uneven outdoor ground areas.

Pros

- Large platforms allow for heavier weight capacity.

- Scissor design can add stability.

- Come in models that can be used indoors or outdoors.

- Generally cheaper to rent than a boom lift.

Cons

- Cannot reach as high as the greatest heights reached by a boom lift.

- Not as maneuverable as a boom lift.

- Must be placed directly adjacent to the work area for best access.

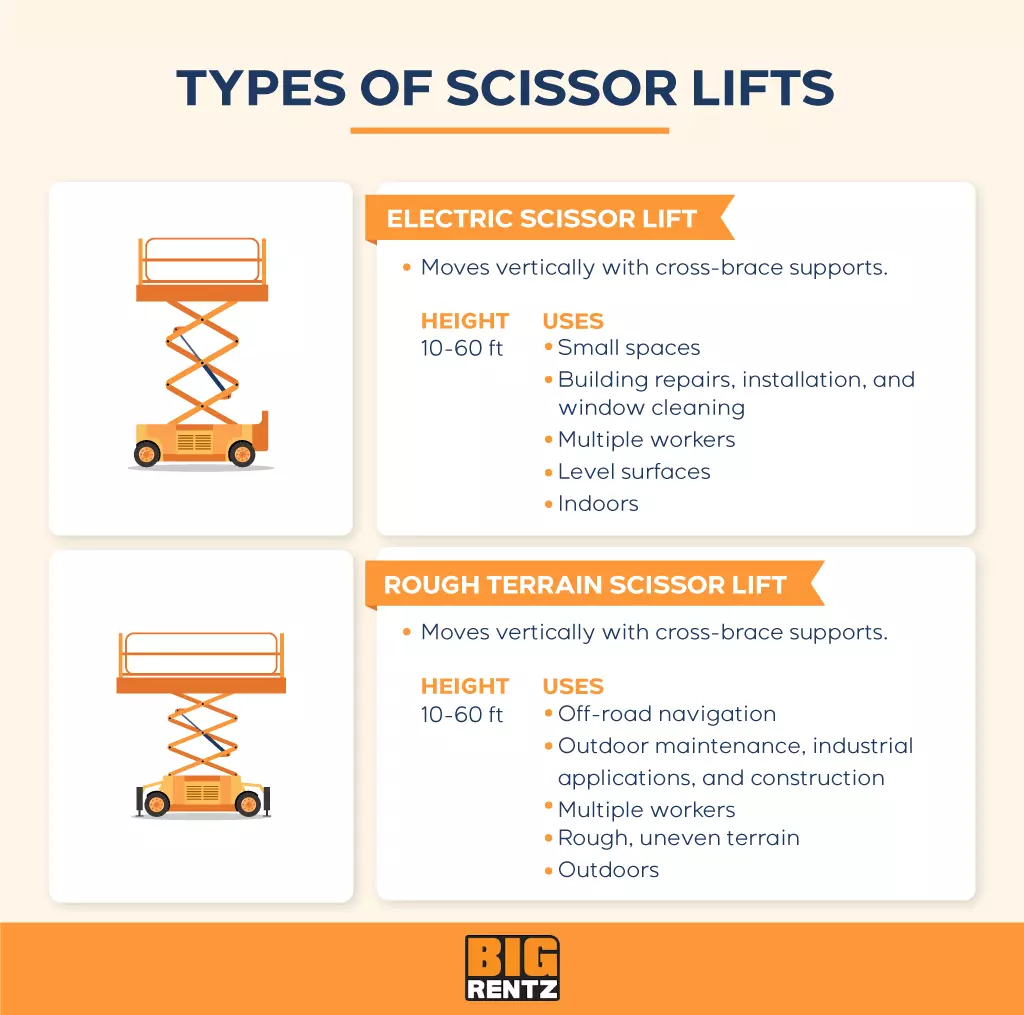

Types of Scissor Lifts

Scissor lifts come in a number of variations, based on their intended use and how they’re powered.

- Electric

- Ideal for indoor use.

- Maneuverable in tight spaces.

- Zero emissions; good for the environment and enclosed spaces.

- Quiet.

- Diesel

- More powerful than other kinds of scissor lifts.

- Can carry more weight in the form of workers and material.

- Used for four-wheel-drive lifts equipped to handle rough terrain.

- Hydraulic

- Use hydraulic liquid in cylinders to lift loads.

- Good for use by workers with minimal training.

- Pneumatic

- Use air pressure to raise and lower the platform.

- Zero emissions; good for indoor use.

- Economical because they use less power.

- Good for smaller projects.

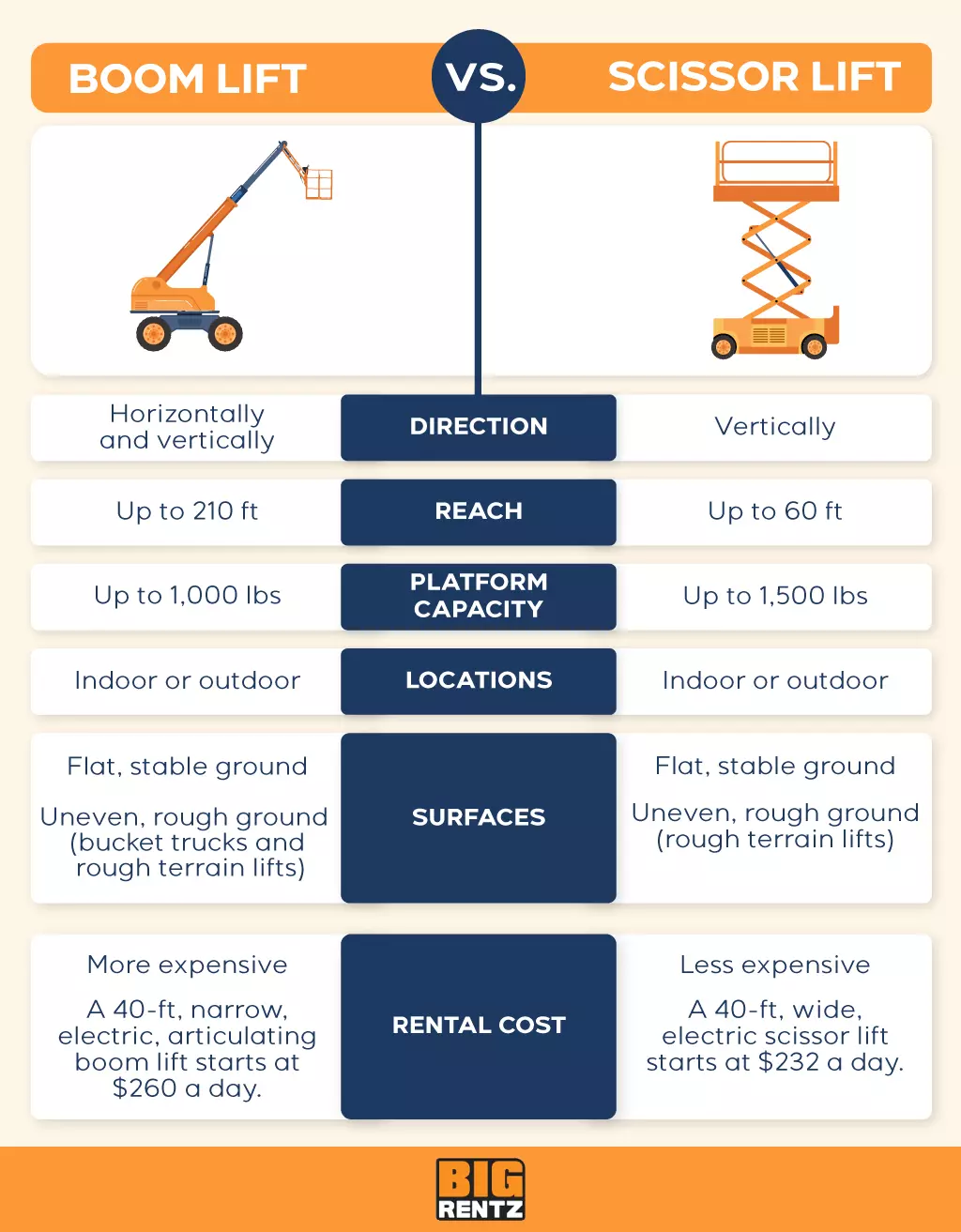

Boom Lift vs. Scissor Lift

When thinking about what kind of lift to rent, take stock of what kind of job you’re doing, where you’re doing it, how much power you need, and your budget. There’s a big range in the price for renting different types of lifts, whether you’re looking at boom lifts or scissor lifts.

Here are a few factors you can consider:

- How high do you need to go? Boom lifts, in general, can give you access to areas that are higher up, while scissor lifts can be a good choice for areas up to 50 feet high, depending on the area where you’re working.

- What direction do you need to move in? If you need to go straight up and down, a scissor lift could be a good choice.

- How many workers are involved? Boom lift buckets have limited space and typically accommodate single workers. Scissor lifts can often accommodate more workers and have a higher weight limit.

- What is the jobsite terrain? Rough terrain scissor lifts and boom lifts, powered by diesel fuel, can be effective on uneven or rocky terrain.

- What is your budget? Boom lifts can range in price from $468 to $3,227 a week, depending on how big they are and what they can do. Scissor lifts are generally cheaper, ranging from $230 to $993 a week.

Height

- Boom lift: Telescopic lifts can raise workers anywhere from 30 to 210 feet; articulating lifts can extend from 30 to 135 feet. The most versatile can go two or even three times higher than a scissor lift, to reach areas that may otherwise be too far up.

- Scissor lift: Scissor lifts can raise workers up to 60 feet, which can allow them to reach many worksites, raising workers up to 4 stories high.

Direction

- Boom lift: Many lift bases can rotate workers 360 degrees. Telescopic lifts can direct workers straight up or outward, or a combination of the two. Articulating lifts can go even further, providing access around obstacles in tight spaces.

- Scissor lift: Scissor lifts are limited to straight up-and-down (vertical) lifts, so workers need to be adjacent to the area they’re working on.

Platform capacity

- Boom lift: Boom lifts can carry up to 500 pounds, making them effective for small and moderate loads.

- Scissor lift: Heavier models can bear heavier loads. For example, A 19-foot electric lift might be able to lift 500 to 700 pounds, while a 50-foot rough-terrain scissor lift might carry up to 2,250 pounds.

Terrain

- Boom lift: Diesel boom lifts may be equipped with tough treading on their tires, making them well-suited to outdoor maintenance and construction jobs. They can be used on uneven, rutted, or rocky ground.

- Scissor lift: Some models come with four-wheel-drive engines and are fueled by powerful diesel engines that are specifically designed to work on rough terrain.

Budget

Boom lifts are typically more expensive than scissor lifts.

- Boom lift: A 40-foot, electric articulating boom lift can cost you $728 a week.

- Scissor lift: A 40-foot, electric scissor lift can cost you $630 a week.

Lift Safety

Aerial lifts such as boom and scissor lifts can pose a number of hazards, including falls, structural failures, electrical accidents, and tip-overs. Lift safety is important and includes several factors. There’s also a risk of lifts hitting objects around them or overhead.

The Occupational Safety and Health Administration (OSHA) requires employers to provide workers with training and necessary personal protective equipment before operating any kind of aerial lift.

This includes procedures for dealing with hazards, instruction on how to operate the lift, how to perform inspections, and how to recognize potentially unsafe conditions — and avoid them. Lift operators should have and use the proper safety equipment and refrain from overloading lifts.

Operators should be familiar with and follow manufacturers’ guidelines.

Explore All Boom Lifts Explore All Scissor Lifts