Operating equipment like skid steers, compact track loaders and mini excavators effectively requires best practices in maintenance and a good understanding of your machine’s hydraulic system. Compact excavators pack a powerful punch and some mini excavator attachments can push your equipment to the limit, causing overheating issues or serious equipment damage. Understanding how to keep your equipment running smoothly, without damage or safety risks is key to efficient operation.

Operating equipment like skid steers, compact track loaders and mini excavators effectively requires best practices in maintenance and a good understanding of your machine’s hydraulic system. Compact excavators pack a powerful punch and some mini excavator attachments can push your equipment to the limit, causing overheating issues or serious equipment damage. Understanding how to keep your equipment running smoothly, without damage or safety risks is key to efficient operation.

Best Practices for Mini Excavator Attachment Operation

No matter what mini excavator attachments your compact machine is operating, following some regular inspections, and analyzing your auxiliary hydraulic flow for each tool and task should be mandatory. The following checklist includes some of the best practices to get the most from your mini excavator :

- Inspect Your Cooling System

- Know the Auxiliary Flow of Your Machine and Attachments

- Inspect Hoses for Cracking or Damage

- Inspect for Dirt and Debris

Inspect Your Cooling System

Compact excavators and attachments provide exceptional versatility to many earthmoving applications, although some tools and tasks put a heavier burden on your machine than others. Several factors may contribute to a machine overheating including the ambient temperature. Operating a heavy duty tool in high heat is asking for trouble if you haven’t inspected your cooling system.

Many engine failures are related to the coolant, which means many overheating issues can be prevented with proper maintenance. Bobcat recommends coolant changes every 1000 hours or every two years, you should follow your manufacturer recommendations for maintaining your cooling system when running Kubota mini excavator attachments or other OEM equipment. Flushing should be done if the fluid looks questionable and be sure to never mix two or more types of coolants.

Bobcat and many other compact machines use propylene glycol instead of ethylene glycol coolants. If these two are accidentally mixed it causes a “gelling” type of reaction which will certainly cause radiator damage and risk damaging the entire engine. Propylene coolant can come in various colors although ethylene glycol is always green. Bobcat makes their propylene coolant and a unique purple color and the hydraulic fluid is always orange to help prevent maintenance techs from accidentally mixing fluids. Once you decide which type of coolant to use whether one that is mixed with distilled water or an extended life type of coolant you should stick with it and never mix the two.

Know the Auxiliary Flow of Your Machine and Attachments

It is important to make sure the auxiliary flow of your machine is within range for the tools you plan to use and supports the application. Operating mini excavator buckets or mini excavator grapples will most likely not cause the machine to overheat. Operating high capacity John Deere mini excavator attachments like a mulcher, however, on something like a 333G track loader is fine as long as your machine is equipped with the right high capacity hydraulic couplings.

Operating hydraulic attachments like a mini excavator forestry mulcher, tree grinders and fixed tooth mulchers requires a lot of hydraulic capacity and flow. Without the right auxiliary hydraulic quick couplings, applications with these tools in high ambient temperatures can easily result in overheating. Some machines provide an audible alarm to let you know your equipment is close to dangerously overheating. If this warning is not heeded, built-in protections automatically shut down equipment resulting in lost productivity and possible equipment damage.

Inspect Hoses for Cracking or Damage

Any hydraulic oil spills should be cleaned up right away as hydraulic oil can damage coolant hoses. Hydraulic oil tends to weaken and soften hoses, which can lead to a leaking or burst hose over time. Stucchi’s threaded, flat face quick couplers eliminate leaks to protect your equipment and the environment. Stucchi’s VEPHD threaded flat face couplers provide quick-connect without premature wear during heavy duty applications with a flat face design that eliminates leaks on quick release.

Inspect for Dirt and Debris

One of the most common causes of skid loaders or mini excavators overheating is when dirt and debris clogs cooling radiators. Depending on the application and the environment, something like mulching which is continually throwing around dirt, leaves and mud has a high potential to allow contamination into sensitive systems. Mini excavator stump grinders can throw up a lot of sawdust which can quickly clog a radiator. When a radiator gets clogged, it can actually explode and blow right off of the machine. Debris in hydraulic oil can act like a fire starter and poses serious safety risks to operators and the environment.

Blowing off your coolers should be done regularly, every day or multiple times a day when operating in extreme high heat. Evaluating your auxiliary hydraulic flow requirements and using the right auxiliary hydraulic quick couplings will provide the most efficient and productive operation while helping to prevent overheating, machine downtime or damage.

Hydraulic Solutions to Make Your Mini Excavator a Big Tool Carrier

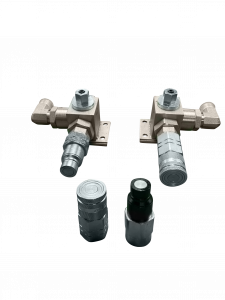

Not every compact machine is equipped with high-capacity auxiliary flow necessary to power some attachments. Stucchi offers a solution with auxiliary hydraulic kits to accommodate high-capacity mini excavator attachments. Make your mini excavator a big tool carrier with our auxiliary hydraulic kit that includes:

- APM Flat Face Couplings

- A-HD Flat Face Couplings

- Hydraulic Adapters

- Ball Valve

- Mounting bracket

Stucchi offers a variety of auxiliary kits and will customize the best solution for your equipment and your application. We offer solutions with hydraulic adapters to your skid steer, compact track loader or mini excavator to get the most out of your equipment safely and efficiently. Helping to prevent equipment overheating improves your productivity and your profits, by eliminating unplanned downtime and costly equipment damage.

Stucchi has been providing a constant flow solutions for more than 60 years, with a hydraulic specialist dedicated to providing the best hydraulic solution to meet your needs. We offer custom solutions with technical expertise in hydraulic specialists experienced in many market segments. Contact us to learn more about improving your land management applications with hydraulic adapters and auxiliary kits to meet the demands of high-capacity mini excavator attachments.