Keywords: hydraulic installation, hydraulic quick connect won’t connect

hydraulic installation

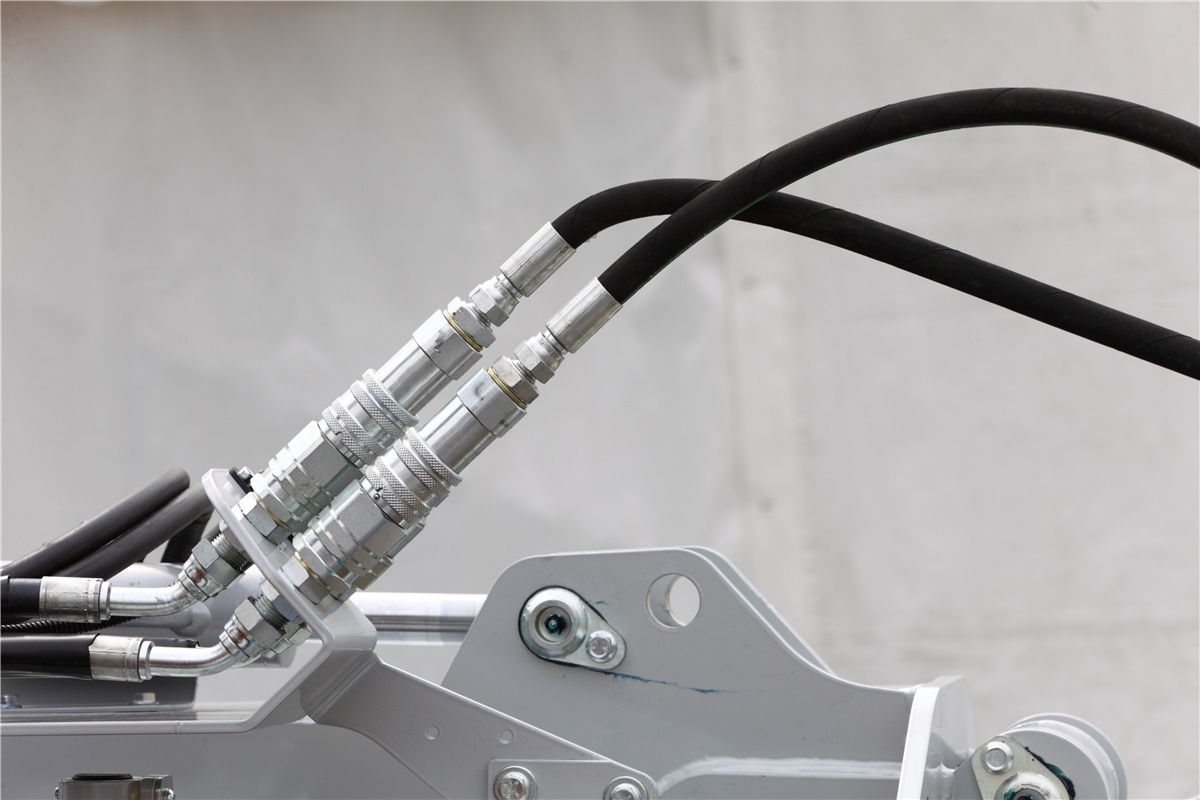

The use of quick couplers on a hydraulic circuit brings great advantages with reference to the speed of assembly and disassembly of the circuit itself and to its portability. It’s important to pay attention to the installation phase to avoid that wrong operations reduce these advantages, or create situations of potential risk for the safety of operators who will connect and disconnect the coupling during the system working life.

This article is about some critical points points related to the installation.

Pre-Installation Knowledge

The indications you’re going to read are valid in general for all types and sizes of quick couplers (screw-on, push-pull, sleeve retraction). It’s important to select a product suitable to the environment where the circuit will work; therefore the use of brass items or – even better – stainless steel ones is strongly recommended in environments with high salinity or if corrosive fluids will flow into the circuit; compounds of gaskets and o-rings must also be compatible with ambient, storage and operating temperatures. It is also necessary to verify that the chemical compatibility between the gasket compounds and the fluids is at least satisfactory.

Tips for Hydraulic Quick Coupler Installation

hydraulic quick connect won’t connect

As mentioned, the installation of quick couplers along a hydraulic line can bring various benefits, but since most of the times these products are “single shut-off” or “double shut-off” type (that is to say, at least one of the two coupler halves and very often both of them are equipped with a valve which prevents fluid spillage and relief of internal pressure in the system after disconnecting the coupler), the presence of one or two valves in the circuit produces a localized increase of the pressure drop. For this reason it’s pretty important to avoid installing, unless strictly necessary, elbow fittings or any type of restriction of the line which may produce further localized losses of fluid energy.

Fluid flow direction doesn’t generally matter too much because it usually doesn’t affect significantly the hydraulic performance of the quick coupler. Just be careful about this point when installing check valves instead, or quick couplers with an integrated check valve.

When designing a hydraulic line it’s important to keep in mind to reserve some space also for protective dust caps to be mounted on the quick couplers.

Troubleshooting Common Installation Problems

Most frequent trouble experienced after an unperfect installation is leak; let’s see how to avoid that from happen. Quick couplers, as well as other circuit components like tubes and fittings, should be carefully inspected before and after the installation to verify that there aren’t scratches or imperfections which could result in fluid leakages; attention must also be paid to a correct orientation of nuts and ferrules. Metal shavings or debris resulting from tube cutting must be removed prior the installation, to avoid damages to o-rings and seals.