Keywords: cat excavator buckets, excavator boom arm bucket

A skid steer is one of the most versatile and capable machines you can have on your farm, ranch or construction site. They are small enough to fit in constricted areas but powerful enough to get the job done. However, a skid steer without an attachment is like a semi without its trailer — unutilized potential. With the right attachment, you can use a skid steer for almost anything.

With that in mind, it is worthwhile to get familiar with your attachments so you can fulfill that untapped potential, starting with basics like how to change skid steer attachments safely and the features and specifications that are relevant to different work tool designs. Follow this guide for all you need to know about attaching attachments to your skid steer!

Table of Contents

- How to Change Skid Steer Attachments

- Skid Steer Attachment Compatibility

- Types of Skid Steer Attachments and How They Operate

- Get the Highest-Quality Skid Steer Attachments at Stinger Attachments

How to Change Skid Steer Attachments

Before you change out the bucket on your skid steer, there are a few rules and terms you need to know about the attachment process.

Safety First

Regardless of the type of skid steer attachment you are switching out, your safety and that of anyone else in the machine’s vicinity is a vital consideration. As such, you will want to be keenly aware of your surroundings when changing skid steer attachments to ensure no one gets hurt.

To switch attachments safely, first find a flat surface that is clear of rocks or other debris that could create potential hazards. After finding a suitable location, make sure anyone in the area knows to stand clear of the skid steer as you change the attachment.

Secondly, safe skid steer attachment operation also requires you to consider the surrounding property and have a thorough knowledge of operating the machine to prevent property damage or harm to the machine itself. As part of having that comprehensive understanding of how to use the skid steer, it is equally important to know the functions of each attachment and how to switch them out properly.

Manual vs. Quick Attach

One of the critical things to know about changing any skid steer attachment is if your machine has a quick attach or manual attachment system. A newer skid steer most likely has quick attach capabilities, but an older model may not have this feature.

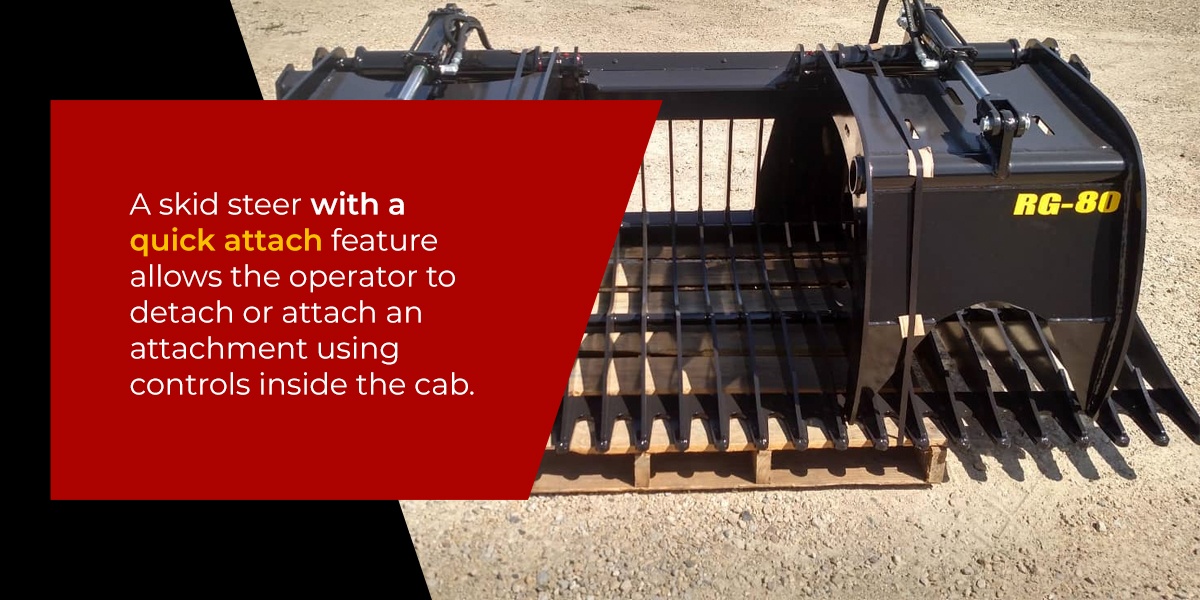

Quick Attach

A skid steer with a quick attach feature allows the operator to detach or attach an attachment using controls inside the cab rather than having to exit the machine and connect the unit manually. The quick attach controls will likely be located on the side panel of your machine. Thus, to detach a skid steer attachment via quick attach, you will need to:

- Drive the skid steer to a spacious location with a flat surface.

- Ensure the attachment is clear of debris like mud, rocks, ice, sticks or other material.

- Lower and tilt the attachment so its bottom lies flat on the ground.

- Press and hold the quick attach release button on your side panel until the attachment is released.

- Check your surroundings, then slowly reverse the skid steer to dismount from the attachment completely.

For mounting an attachment to the skid steer, the attachment should be placed in a spacious area so you can easily line up the skid steer arms and coupler with the tool’s mounting plate. With that in mind, the steps required to mount a skid steer attachment via quick attach include:

- Lower and tilt the skid steer arms and coupler so they line up with the attachment and lie flat against the mounting plate.

- Once the arms and coupler are in place with the attachment, raise and tilt them to their proper position.

- Press and hold the quick attach engagement button on your side panel until the attachment is securely locked in.

- Check your surroundings, then tilt the attachment downward and slowly reverse the skid steer to confirm the connection.

- Perform a final check by lifting the attachment slightly off the ground to ensure that everything is secure and the levers or pins are in the correct position.

Though quick attach skid steers can save you a lot of time on the job, they still require you to connect and disconnect any hydraulic cables from the attachment manually. Thus, you will need to exit the cabin after securely attaching or releasing the tool to connect or disconnect the hydraulic cables. When attaching, ensure you connect any cables before moving on from step four to step five. The ends of the cables should be cleared of dust and debris before connecting them to the skid steer.

A more efficient option is to have a helping hand connect or disconnect the cables after the attachment is secured or released, as long as they know to stand clear of the machine while you are actively operating it. Once the cables are hooked up, turn on the auxiliary hydraulics inside the skid steer to make sure everything is in working order and that there are no hydraulic leaks from the cables.

Manual Removal and Attachment

Skid steers that do not have a quick attach feature require the operator to exit the cab after lining up the machine or driving the skid steer to the attachment drop-off location. For manually removing an attachment, you will need to:

- Drive the skid steer to a spacious area with a flat surface to dismount the attachment.

- Exit the cab after powering down the machine.

- Remove any dirt and debris from the attachment.

- Lift the lock pins or levers that secure the attachment to the skid steer.

- Disconnect any hydraulic cables and place them on the attachment — make sure they are not hooked on any edge of the skid steer. To disconnect the cables, you can push the couplers in or out (depending on if the cable has a male or female end) to release the pressure. You can also press the auxiliary hydraulic pressure relief button inside the skid steer if that option is available.

- Hop back into the cab, check your surroundings, tilt the skid steer arms to free them from the attachment and reverse the machine.

When manually mounting an attachment to the skid steer, the operator must:

- Drive the skid steer to where the attachment is stored and line up the arms to lie flat against the tool’s mounting plate.

- Once the arms and coupler are in place, raise and tilt them to their proper position.

- Once the skid steer’s arms and attachment are lined up, turn off the machine and exit the cab.

- Maneuver the lock pins to secure the attachment to the skid steer.

- Clear any dust or debris from any hydraulic cable connections on the attachment and connect them to the skid steer according to the operation and maintenance manual (OMM). The hoses will have male and female couplers, and you should hear a clicking sound when they are connected. You can also pull on them to make sure they are securely attached.

- Hop back in the cab and make sure your surroundings are clear.

- Tilt the attachment downward and slowly reverse the skid steer to ensure the attachment is securely in place.

- Perform a final check by lifting the attachment slightly off the ground to ensure everything is secure and the levers or pins are in the correct position.

Skid Steer Attachment Compatibility

While you may occasionally come across a skid steer attachment with some eccentricities that are only compatible with a particular brand or model of skid steer, the majority of modern skid steers and attachments made today are manufactured to be universally compatible with each other — even some lawn and garden equipment is skid-steer compatible. At Stinger Attachments, we make all our attachments with universal mounting plates that will hook up to any modern skid steer you own, whether it comes from Caterpillar, Kubota or Bobcat.

However, there are additional factors to consider with the compatibility of skid steer attachments beyond that of the mounting plate, such as the total weight of the attachment and the load-bearing capacity of the skid steer. All skid steers have a maximum weight rating that they can lift, so you will want to make sure the weight of any attachment you purchase is well below that maximum rating for safe operation so you can still add heavy loads while working.

The maximum load-bearing capacity of your skid steer should be indicated in the OMM. As for the size and weight of the attachment, the manufacturer and distributor will usually have different options you can choose from to ensure the attachment is the right size for your skid steer. If information on the size, weight and load-bearing capacity of the attachment is not readily available when viewing the product online or in-store, ask an employee or customer service representative for its specifications before buying.

Another factor you may want to consider when comparing the specs of the attachment and the requirements of your particular skid steer is the setup of the hydraulics, so be sure to ask about those specifications to make sure the tool will work with your machine.

Even if your skid steers and attachments are not universally compatible with each other, it is also essential to have a comprehensive understanding of each skid steer attachment you own and how it operates.

Types of Skid Steer Attachments and How They Operate

Skid steer attachments come in many different sizes and configurations to match the demands of any task you throw at them. You’ve got various kinds of grapplers that can dig and sift through rock like a hot knife through butter, buckets for manure, rock and other material with or without teeth, attachments that can yank a tree straight out of the ground or drill deep into the dirt to plant a new one, and other attachments for just about any purpose you can think of!

Here are some of the popular skid steer attachments we provide at Stinger Attachments:

1. Grapples

There are a variety of grapple attachments you can choose from suited to different purposes, including single- or dual-claw grapples, manure grapples, rock grapples and root grapples, as well as grapple-bucket combinations. Some dual-claw grapples come with independent movement so you can operate each grapple on its own or in tandem. All of our grapples at Stinger Attachments are made with a minimum of grade-50 steel, offer greaseable pivot points, and arrive fully assembled and ready for use.

2. Tree Pullers

Our STP-34 Skid Steer Tree Puller Attachment is made from grade-50 structural steel and comes with a 34-inch jaw opening that can pull any tree 10 inches in diameter out of the earth like a loose tooth. The jaws on the STP-34 Tree Puller are 3/4 inches thick and built with A-36 fully welded steel. A tree guard and safety step are also built into the attachment so you can operate it safely without concern that the tree might fall back on you.

3. Pallet Forks

With pallet forks and a sturdy skid steer, there is not much you won’t be able to lift and move around. As with all of our steel at Stinger Attachments, our pallet forks are manufactured with 50-grade structural steel, allowing them to boast an impressive 8,000-pound capacity. Our pallet forks are also designed with a safety step and walk-through design to ensure your operations proceed as safely as possible.

4. Buckets

A classic bucket attachment is a must-have for any farmyard or construction site operation. However, as with grapple attachments, there is a huge variety of options when it comes to skid steer buckets. Along with having different depths and sizes, many buckets are designed for specialized purposes. Options include rock buckets that have tine bottoms and grapple attachments, material buckets with a solid base for dirt, sand and other like substances, manure buckets with spaced-out tines and grapples, and several others.

Other skid steer attachments we sell include bale spears, auger drives and trenchers, land planes, soil conditioners, snow equipment, concrete attachments, brooms and sweepers, and more! If you would like more information on any of these attachments and how they operate, please feel free to contact a member of our world-class customer service team.

Get the Highest-Quality Skid Steer Attachments at Stinger Attachments

We aren’t exaggerating when we say our skid steer attachments are the highest quality you can find. At Stinger Attachments, we are fully convinced of the superiority of our products. That commitment to the highest-quality products also extends to our customer service team, as we will not rest until we have resolved or answered any concern or question you have to your satisfaction. We can help you pick a tool for your skid steer, learn how to attach it and even provide advice on using it effectively.

To that end, we also match the quality of our skid steer attachments with excellent pricing, quick shipping with competitive rates and a one-year warranty. You can trust our skid steer attachments to get the job done, whatever the task.

Contact us today if you need more information about our products or if there is a particular attachment you want to buy from us!